One way to test a design for stability to lateral forces is to use a shake table. Some of the world's tallest buildings, like the Petronas Towers, are an excellent example of this type of design because Malaysia is in an area that experiences frequent earthquake activity. If an engineer is going to design a building in earthquake country, then they need to be sure that their design can withstand lateral forces. Earthquakes occur when the earth's tectonic plates, which are slowly moving relative to each other, get stuck for a while and then suddenly come loose. One type of force that can weaken a structure is a lateral (side-to-side) shaking force, like that experienced during an earthquake. If the design is stable, then these forces will not weaken the structure or cause the structure to collapse. Forces come from many sources: gravity, people inside, weight of building materials, weather, and environmental impacts. The Burj Khalifa in the city of Dubai, United Arab Emirates (Wikipedia user Donaldytong).Īn engineer designs a building to withstand forces, or things that push and pull on the building.

"The Effect of Structural Height on Building Stability," Selah Intermediate School, Selah, WA.įigure 1. Retrieved March 6, 2007, from this URL, but no longer available online: "The Effect of Wind Load on a Building ," Selah Intermediate School, Selah, WA. Learning With LEGO: School-University Partnership (SUP) for Earthquake Engineering Education, Pacific Earthquake Engineering Research Center (PEER). Shake Table for Testing Structures in Earthquake Country, Resource Area for Teaching (RAFT), San Jose, CA. This project idea is based on a simple design for a shake-table posted on RAFT, the Learning with LEGO PEER project at UC Irvine, and science fair projects posted from Selah Intermediate School in Selah, WA: LEGO is a registered trademark of the LEGO Group. The company is awaiting approval for its 220-floor building, called Sky City, which will also be in Changsha.Edited by Ben Finio, PhD, Science Buddies “This is definitely the fastest speed in our industry.” The company had honed its technology to speed up its construction from two floors to three floors a day, he added. The first 20 floors were completed last year, and the remaining 37 were built from 31 January to 17 February this year, Xiao said. The structure is safe and can withstand earthquakes, according to Xiao.īroad Sustainable Building spent four and a half months fabricating the building’s 2,736 modules before construction began.

Mini Sky City has 19 atriums, 800 apartments and office space for 4,000 people, with space in the building going on sale in May.

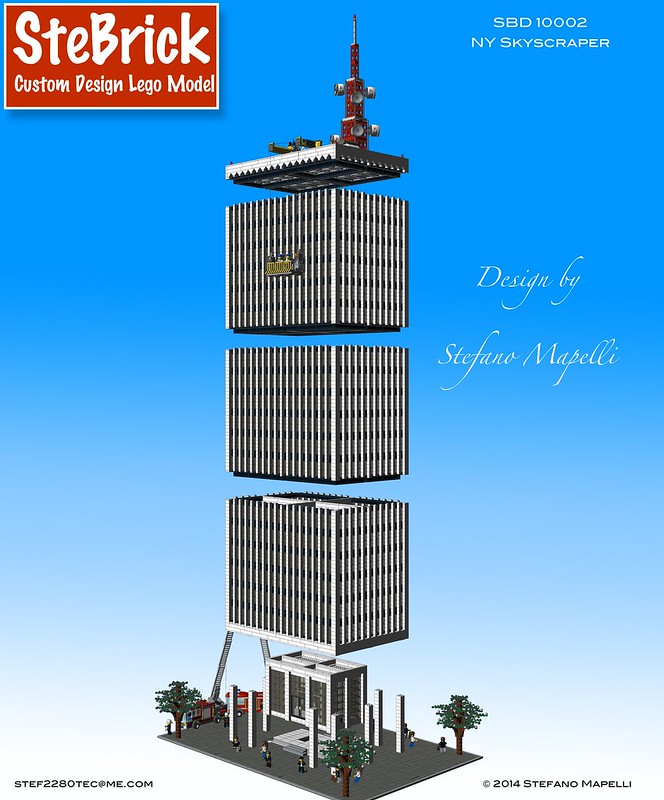

“People nowadays want more personalised architecture.” “But it is not perfect, and it does not meet all kinds of personalised demands,” Liu said. Liu Peng, the associate director of the engineering consulting firm Arup Beijing, said the method was worth developing because it could become a safe and reliable way to build skyscrapers quickly. Some critics say the method could lead to cityscapes with overly uniform architecture. Modular methods have been used for high-rise apartment blocks elsewhere, including in Britain and the US. “With the traditional method they have to build a skyscraper brick by brick, but with our method we just need to assemble the blocks,” the company engineer Chen Xiangqian said. Its time-lapse video of the rapid build has become popular on Chinese video sharing sites since it was first uploaded to YouTube. It worked on Mini Sky City in two bursts interrupted by bad weather. The rectangular, glass and steel building has 19 atriums, 800 apartments and office space for 4,000 people.

0 kommentar(er)

0 kommentar(er)